Next week I’m going to the Free Software and Open Source Symposium. It’s always worth going, and especially so this year, there are several great speakers for sure and many more with potential.

One of the things running during the symposium is a Robots competition. My humble contribution to this competition is the design of the PCB – a printed circuit board to hold in place the ultrasonic sensors, connectors for the bumper switches and motors, and the resistors needed to make sure the sensors don’t fry the Raspberry Pi.

A very simple circuit, but the last time I made my own circuits I had to design them using pencil and paper and make them by painting my circuit on with oil-based paint, so it would protect the copper I wanted to keep as the acid dissolved the rest of it.

At Seneca we have a machine that will very precisely cut out the PCB for us. But that machine needs instructions and those instructions are created by software. At first I thought I’d never get to give that a shot because they suggest proprietary software on Windows but then John Selmys found that you can use Fritzing, and it can export into the same Etched Gerber RS-274X which the lab needs. Woo!

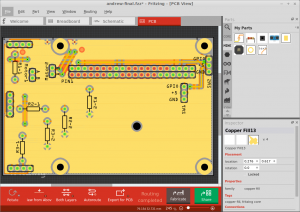

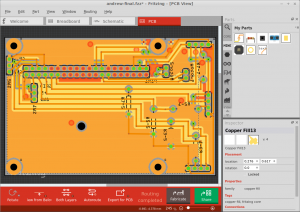

There was definitely a learning curve, but given that this is my first encounter with this kind of software, I’m quite happy with the results. It took 6 tries but finally I got the design right. Here it is, a double-sided PCB design with a ground fill:

Next week we’ll get 5 of these printed and assemble them and then I’ll post some more photos.